Application

-

Home appliances

Can help with the installation, removal, repair and adjustment of home appliances. Carbide materials are usually used to make cutting tools and cutters, which can be used to process various materials, such as metal, wood, plastic, etc., and play an important role in the manufacturing process of home appliances.check details -

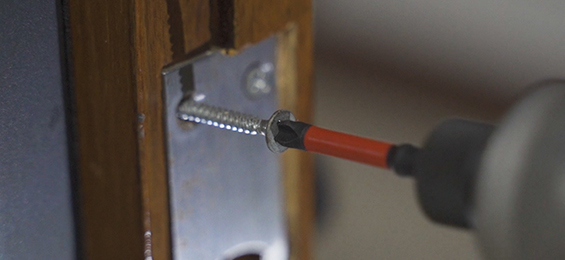

furniture

It has the following functions in furniture production: Installation and assembly: These tools can be used to tighten screws and install furniture components such as chairs, tables, cabinets, etc. Repair and adjustment: These tools can be used for furniture repair and adjustment, such as adjusting the structure of furniture, replacing screws, etc. Making holes: Glass hole openers and marble hole openers can be used to create holes in furniture, such as those for installing glass panels or marble countertops. Making tools and parts: Carbide can be used to make cutting tools and parts needed in the furniture manufacturing process, improving processing efficiency and quality.check details -

monitor

Various roles may be played in the field of surveillance: Security Surveillance: These tools may be used to install and maintain surveillance equipment, such as the set screws needed to install cameras, sensors or security devices. Maintenance and adjustment: Tools such as electric and pneumatic screwdrivers, Allen wrenches, screwdrivers, sockets, etc. may be used to monitor the maintenance and adjustment of the equipment to ensure its normal operation. Positioning and installation: Glass hole openers, marble hole openers, and carbide products may be used to position and open holes during the installation of monitoring equipment so that it can be firmly installed in the appropriate location.check details -

assembly line

In the production line, these tools and equipment may play the following roles: Assembly and disassembly: Electric and pneumatic screwdrivers, Allen wrenches, screwdrivers and sockets may be used for assembly and disassembly of products on the assembly line, screws and nuts for installing and disassembling parts or products, etc. Processing and positioning: Glass hole openers, marble hole openers, and carbide products may be used for processing and positioning products on the assembly line, for drilling, opening, or fixed positioning of products. Improve production efficiency: These tools and equipment can help speed up the assembly, disassembly and processing of products, thereby improving production efficiency and quality.check details -

furniture

It has the following functions in furniture production: Installation and assembly: These tools can be used to tighten screws and install furniture components such as chairs, tables, cabinets, etc. Repair and adjustment: These tools can be used for furniture repair and adjustment, such as adjusting the structure of furniture, replacing screws, etc. Making holes: Glass hole openers and marble hole openers can be used to create holes in furniture, such as those for installing glass panels or marble countertops. Making tools and parts: Carbide can be used to make cutting tools and parts needed in the furniture manufacturing process, improving processing efficiency and quality.check details -

Magnetizer

These tools appear to be on the list of "works in magnetizers". In this case, assume that "magnetizer" refers to a device used to magnetize tools or parts. Here's how these tools might play a role in a magnetizer: Electric and air-operated screwdriver bits, screwdrivers, sockets and Allen wrenches may need to be magnetized to ensure that they can effectively attract and tighten screws or nuts when used, thereby improving work efficiency and accuracy. Glass hole openers, marble hole openers, and carbide tools may need to be magnetized to allow for easier positioning and retention on the work surface while in use, thereby increasing precision and safety. Magnetizing these tools and equipment may help improve their efficiency and convenience in actual production operations.check details

Chinese

Chinese